Introduction

Building facades serve as the primary barrier between interior and exterior environments, protecting occupants from weather, maintaining thermal comfort, and ensuring structural integrity. However, facades are subject to constant environmental stress, leading to deterioration, defects, and failures that can result in air and water leakage—two of the most common and costly building envelope problems.

Traditional inspection methods for detecting air and water leakage often involve visual examination, water testing, or destructive testing techniques. These methods, while valuable, have significant limitations including limited access, subjective assessment, and inability to detect hidden problems behind facade materials.

Thermal imaging technology, when integrated with drone systems, revolutionizes facade inspection by enabling non-invasive detection of air and water leakage with unprecedented accuracy and efficiency. This article explores how thermal imaging drones detect air and water leakage in building facades, providing facility managers and building owners with critical information for maintenance planning and problem resolution.

Understanding Air and Water Leakage in Facades

The Problem of Air Leakage

Air leakage occurs when uncontrolled air movement passes through the building envelope, resulting in:

Energy Loss

- Heating and Cooling Inefficiency: Conditioned air escapes, requiring increased energy consumption

- HVAC System Strain: Systems work harder to maintain comfort levels

- Increased Operating Costs: Higher utility bills and maintenance expenses

Comfort Issues

- Temperature Variations: Uneven heating and cooling

- Draft Problems: Uncomfortable air movement

- Humidity Control Challenges: Difficulty maintaining optimal humidity levels

Moisture Problems

- Condensation: Warm, moist air meeting cold surfaces

- Mold Growth: Moisture accumulation in hidden areas

- Structural Damage: Long-term moisture-related deterioration

The Problem of Water Leakage

Water leakage through facades causes:

Immediate Damage

- Interior Water Damage: Staining, warping, and material degradation

- Electrical Hazards: Water contact with electrical systems

- Occupant Disruption: Damage to contents and operations

Long-Term Consequences

- Structural Deterioration: Compromised building materials

- Mold and Mildew: Health concerns and material damage

- Corrosion: Metal component deterioration

- Reduced Building Lifespan: Accelerated aging and failure

How Thermal Imaging Works

Principles of Thermal Imaging

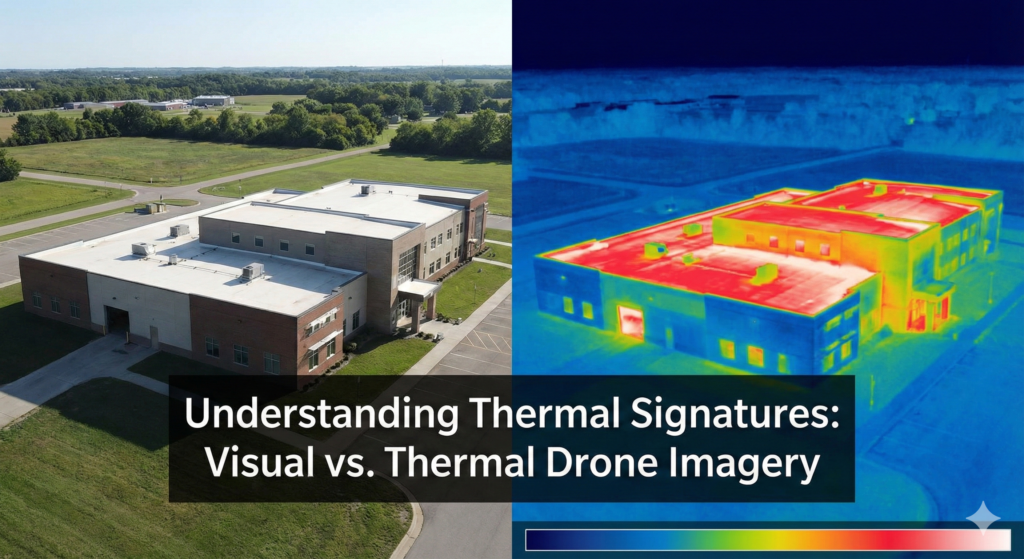

Thermal imaging cameras detect infrared radiation (heat) emitted by all objects. Different temperatures appear as different colors or shades in thermal images, allowing identification of:

- Temperature Variations: Differences indicating problems

- Heat Patterns: Anomalies revealing hidden issues

- Energy Loss: Areas of thermal inefficiency

- Moisture Presence: Water affecting thermal properties

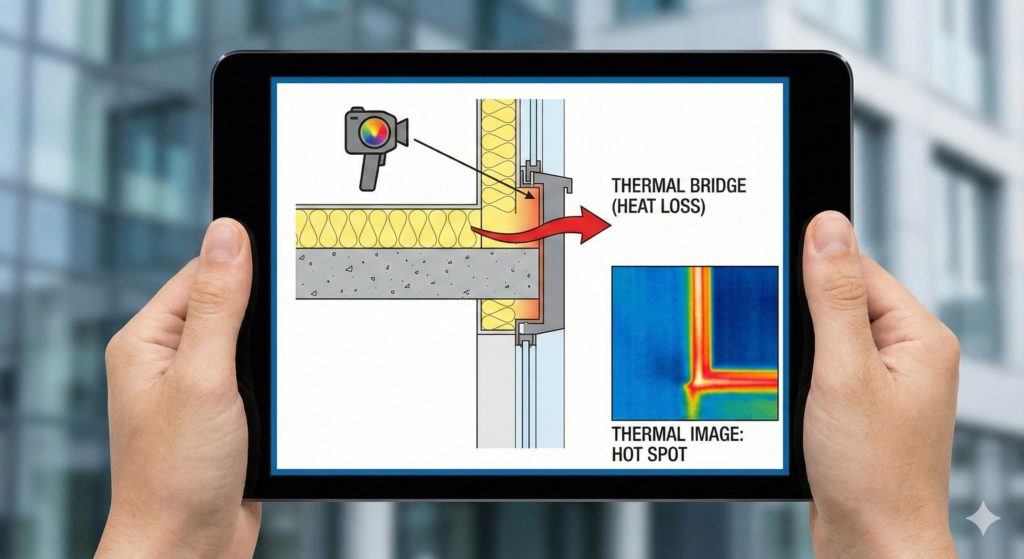

Why Thermal Imaging Detects Leakage

Air Leakage Detection

Air leakage creates temperature differences:

- Cold Air Infiltration: In winter, cold air entering creates cool spots

- Warm Air Exfiltration: In summer, conditioned air escaping creates warm spots

- Thermal Bridging: Air movement through gaps creates temperature anomalies

- Insulation Gaps: Missing or compromised insulation shows as temperature variations

Water Leakage Detection

Water affects thermal properties:

- Thermal Conductivity: Water conducts heat differently than dry materials

- Evaporative Cooling: Moisture evaporation creates cool spots

- Capillary Action: Water migration creates characteristic thermal patterns

- Material Saturation: Wet materials have different thermal signatures

Drone-Based Thermal Imaging Systems

Advantages of Drone Integration

Access and Coverage

- Hard-to-Reach Areas: Access to all facade areas without scaffolding

- Comprehensive Coverage: Complete building inspection in single operation

- Safety: No workers at height

- Efficiency: Rapid inspection of large buildings

Optimal Positioning

- Consistent Distance: Maintaining optimal distance for thermal imaging

- Multiple Angles: Capturing images from various perspectives

- Close-Up Detail: Detailed examination of specific areas

- Context Views: Understanding overall thermal patterns

Data Quality

- Stable Platform: Drones provide stable platforms for high-quality imaging

- Consistent Conditions: Controlled imaging conditions

- High Resolution: Detailed thermal data capture

- Georeferencing: Precise location data for each image

Technical Capabilities

Modern thermal imaging drones feature:

- High-Resolution Thermal Sensors: Detailed temperature data

- Radiometric Capabilities: Precise temperature measurement

- Multiple Spectral Bands: Enhanced detection capabilities

- Real-Time Analysis: Immediate identification of issues

- Integration with Visual Cameras: Combining thermal and visual data

Detection Methods and Techniques

Air Leakage Detection

Pressure Differential Method

- Building Pressurization: Creating pressure difference between interior and exterior

- Thermal Scanning: Identifying air movement through thermal anomalies

- Quantitative Analysis: Measuring leakage rates and locations

- Comprehensive Mapping: Documenting all leakage points

Seasonal Analysis

- Winter Inspections: Detecting cold air infiltration

- Summer Inspections: Identifying warm air exfiltration

- Comparative Analysis: Understanding patterns across seasons

- Comprehensive Assessment: Complete understanding of air leakage

Water Leakage Detection

Active Detection

- Controlled Moisture Introduction: Applying water to identify pathways

- Thermal Monitoring: Tracking water movement through thermal changes

- Pattern Recognition: Identifying characteristic leakage patterns

- Source Identification: Locating entry points

Passive Detection

- Natural Moisture Presence: Detecting existing water problems

- Thermal Anomalies: Identifying areas with moisture-related temperature differences

- Historical Comparison: Comparing with previous inspections

- Pattern Analysis: Understanding moisture migration

Interpreting Thermal Images

Understanding Thermal Signatures

Normal Patterns

- Uniform Temperature: Consistent thermal appearance across similar materials

- Expected Variations: Normal temperature differences (shading, orientation)

- Material Characteristics: Different materials showing expected thermal properties

Anomaly Indicators

- Unexpected Cool Spots: Potential air infiltration or moisture presence

- Unexpected Warm Spots: Air exfiltration or insulation problems

- Linear Patterns: Indicating gaps, cracks, or joints

- Irregular Patterns: Suggesting material problems or hidden issues

Common Leakage Patterns

Air Leakage Patterns

- Perimeter Gaps: Around windows, doors, and openings

- Joint Failures: Between facade panels or components

- Penetration Points: Around pipes, conduits, and fixtures

- Insulation Gaps: Missing or compromised insulation

Water Leakage Patterns

- Vertical Streaks: Water running down surfaces

- Concentrated Areas: Localized moisture accumulation

- Spreading Patterns: Water migration through materials

- Entry Points: Specific locations where water enters

Applications in Dubai and UAE

Climate Considerations

The UAE’s climate presents unique challenges:

High Temperatures

- Thermal Stress: Extreme temperature variations

- Material Expansion: Thermal expansion and contraction

- UV Degradation: Sunlight damage to facade materials

- Thermal Imaging Advantages: Clear thermal signatures in hot climate

Humidity and Moisture

- High Humidity: Increased moisture-related problems

- Condensation Issues: Temperature differences causing condensation

- Salt Air: Coastal areas with corrosive conditions

- Thermal Detection: Effective moisture identification

Building Types

High-Rise Buildings

- Access Challenges: Difficult inspection of tall structures

- Comprehensive Coverage: Drones enable complete inspection

- Safety Benefits: No workers at extreme heights

- Efficiency: Rapid inspection of large facades

Commercial Facilities

- Operational Continuity: Minimal disruption to operations

- Comprehensive Assessment: Complete building envelope evaluation

- Maintenance Planning: Data for effective maintenance programs

- Cost Efficiency: Identifying problems before they escalate

Residential Buildings

- Occupant Safety: Identifying problems affecting residents

- Energy Efficiency: Improving building performance

- Property Value: Maintaining building condition

- Comprehensive Documentation: Records for property management

Best Practices for Thermal Imaging Inspections

Planning and Preparation

Optimal Conditions

- Temperature Differential: Sufficient difference between interior and exterior

- Weather Conditions: Clear, stable weather for best results

- Time of Day: Optimal times for thermal contrast

- Building Preparation: Ensuring appropriate interior conditions

Equipment Selection

- Appropriate Resolution: Thermal sensors matching inspection requirements

- Radiometric Capabilities: Precise temperature measurement when needed

- Integration: Combining thermal and visual imaging

- Calibration: Ensuring accurate temperature readings

Data Collection

Systematic Coverage

- Complete Coverage: Ensuring all areas are inspected

- Overlapping Images: Comprehensive documentation

- Multiple Perspectives: Various angles for complete understanding

- Close-Up Detail: Detailed examination of identified issues

Quality Control

- Image Quality: Ensuring clear, usable thermal images

- Georeferencing: Precise location data

- Documentation: Comprehensive records of conditions

- Verification: Confirming findings with additional methods when needed

Analysis and Reporting

Professional Interpretation

- Expert Analysis: Trained professionals interpreting thermal data

- Pattern Recognition: Identifying characteristic leakage patterns

- Quantitative Assessment: Measuring severity when possible

- Comprehensive Reporting: Detailed documentation of findings

Actionable Recommendations

- Priority Assessment: Identifying critical issues requiring immediate attention

- Repair Recommendations: Specific guidance for problem resolution

- Maintenance Planning: Long-term maintenance strategies

- Cost Estimation: Budget planning for repairs

Integration with Building Management

Maintenance Planning

Thermal imaging data supports:

- Preventive Maintenance: Addressing problems before they escalate

- Priority Setting: Focusing resources on critical issues

- Budget Planning: Understanding repair costs and timing

- Performance Tracking: Monitoring building envelope condition over time

Energy Efficiency

Leakage detection contributes to:

- Energy Audits: Comprehensive building performance assessment

- Retrofit Planning: Identifying opportunities for improvement

- Performance Verification: Confirming energy efficiency measures

- Compliance: Meeting energy efficiency requirements

Future Developments

Thermal imaging technology continues to advance:

- Higher Resolution: More detailed thermal data

- Enhanced Sensitivity: Detecting smaller temperature differences

- AI Integration: Automated anomaly detection

- Real-Time Analysis: Immediate problem identification

- Predictive Capabilities: Forecasting future problems

Conclusion

Thermal imaging technology, integrated with drone systems, provides a powerful tool for detecting air and water leakage in building facades. This non-invasive, comprehensive approach enables facility managers and building owners to:

- Identify Problems Early: Detecting issues before they cause significant damage

- Plan Maintenance Effectively: Prioritizing repairs based on accurate data

- Improve Energy Efficiency: Reducing energy loss from air leakage

- Protect Building Integrity: Preventing water damage and deterioration

- Ensure Occupant Comfort: Maintaining optimal indoor conditions

For buildings in Dubai and the UAE, where climate conditions create significant challenges for building envelopes, thermal imaging inspections provide essential information for effective maintenance and management.

The combination of advanced thermal imaging technology with drone platforms creates an efficient, safe, and comprehensive inspection solution that supports building performance, energy efficiency, and long-term value preservation.

Ready for Professional Thermal Imaging Inspection?

At ZID – Zenith InnoDev, we combine 11+ years of mechatronics engineering expertise with 4 years of specialized drone services to deliver comprehensive facade inspections using advanced thermal imaging technology.

Our thermal imaging services detect air and water leakage with precision, providing detailed reports and actionable recommendations for building maintenance and energy efficiency improvement. We ensure all operations comply with GCAA regulations while delivering professional-grade results.

Contact us today to schedule a thermal imaging inspection and discover how this technology can protect your building investment and improve performance.

Internal Links: