Introduction

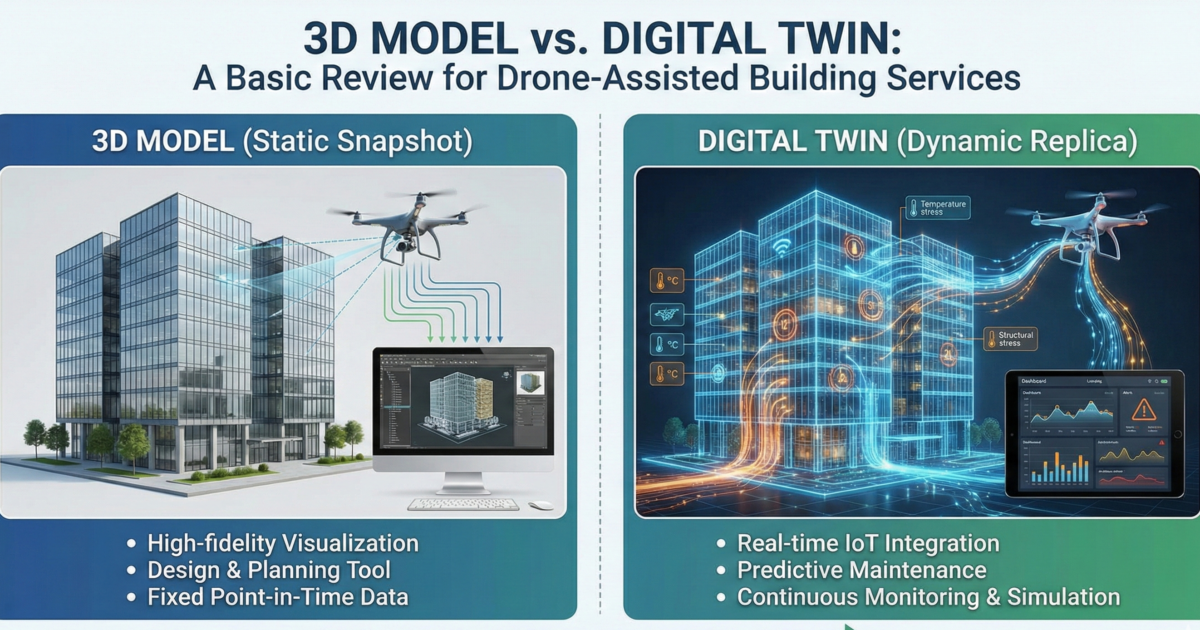

In the rapidly evolving world of digital representation and modeling, two terms frequently cause confusion among professionals: “Digital Twin” and “3D Model.” While these concepts may seem similar at first glance, they represent fundamentally different approaches to digital representation, each serving distinct purposes and offering unique capabilities.

This confusion is understandable—both involve creating digital representations of physical objects or spaces, and both utilize similar technologies like 3D modeling software, photogrammetry, and LiDAR. However, understanding the core differences is crucial for professionals making technology decisions, as choosing the wrong approach can lead to significant inefficiencies, missed opportunities, and wasted resources.

This comprehensive guide clarifies the essential differences between Digital Twins and 3D Models, helping professionals make informed decisions about which technology best serves their specific needs.

Understanding 3D Models

What Is a 3D Model?

A 3D model is a digital representation of a physical object, structure, or space created using three-dimensional coordinates. It captures the geometric and visual characteristics of the subject, providing a static or semi-static representation that can be viewed, analyzed, and manipulated in digital space.

Key Characteristics of 3D Models

Static Representation

3D models are typically static snapshots in time. They represent the subject as it existed at the moment of data capture, without ongoing updates or real-time synchronization with the physical counterpart.

Geometric Accuracy

3D models focus on geometric accuracy, capturing:

- Shape and Form: The physical dimensions and geometry

- Spatial Relationships: How components relate to each other

- Visual Appearance: Surface textures, colors, and materials

- Topology: The structure and connectivity of elements

Data Sources

3D models are created from various sources:

- Photogrammetry: Processing photographs into 3D geometry

- LiDAR Scanning: Precise point cloud data from laser scanning

- CAD Modeling: Manual or semi-automated design creation

- Combined Methods: Integration of multiple data sources

Primary Use Cases

3D models excel in applications requiring:

- Visualization: Presenting designs or existing conditions

- Documentation: Creating records of current states

- Planning: Supporting design and development processes

- Communication: Sharing information with stakeholders

- Analysis: Geometric and spatial analysis

Limitations of 3D Models

While valuable, 3D models have limitations:

- Static Nature: Don’t reflect ongoing changes

- Limited Intelligence: No embedded logic or behavior

- No Real-Time Data: Not connected to live systems

- Analysis Constraints: Limited to geometric and visual analysis

Understanding Digital Twins

What Is a Digital Twin?

A Digital Twin is a dynamic, virtual representation of a physical system that is continuously updated with real-time data from its physical counterpart. It goes beyond geometric representation to include behavioral models, operational data, and predictive capabilities.

Key Characteristics of Digital Twins

Dynamic and Live

Digital Twins are living, breathing digital representations that:

- Update Continuously: Real-time synchronization with physical systems

- Reflect Current State: Always represent current conditions

- Track Changes: Monitor and record changes over time

- Respond to Events: React to changes in the physical system

Integrated Data Systems

Digital Twins integrate multiple data sources:

- IoT Sensors: Real-time data from connected devices

- Operational Systems: Data from building management, manufacturing, or other systems

- Environmental Data: Weather, usage patterns, and external factors

- Historical Data: Long-term trends and patterns

Behavioral Modeling

Digital Twins include:

- Simulation Capabilities: Modeling how systems behave under various conditions

- Predictive Analytics: Forecasting future states and performance

- What-If Scenarios: Testing different operational strategies

- Optimization Algorithms: Identifying optimal configurations

Intelligence and Learning

Advanced Digital Twins feature:

- Machine Learning: Learning from patterns and improving predictions

- AI Integration: Intelligent analysis and decision support

- Automated Responses: Triggering actions based on conditions

- Continuous Improvement: Evolving with accumulated data

Primary Use Cases

Digital Twins excel in applications requiring:

- Operational Monitoring: Real-time system performance tracking

- Predictive Maintenance: Forecasting maintenance needs

- Optimization: Improving efficiency and performance

- Risk Management: Identifying and mitigating risks

- Decision Support: Data-driven decision-making

- Remote Management: Controlling and monitoring from distance

Core Differences: A Detailed Comparison

1. Temporal Nature

3D Model: Static Snapshot

A 3D model represents a specific moment in time. Once created, it remains unchanged unless manually updated. It’s like a photograph—it captures how something looked at a particular moment.

Digital Twin: Living System

A Digital Twin is continuously updated, reflecting the current state of its physical counterpart. It’s like a live video feed that constantly shows what’s happening now.

2. Data Integration

3D Model: Geometric Data

3D models primarily contain geometric and visual data. They focus on shape, size, appearance, and spatial relationships.

Digital Twin: Comprehensive Data

Digital Twins integrate geometric data with operational data, sensor readings, performance metrics, environmental conditions, and more. They provide a holistic view of the system.

3. Purpose and Functionality

3D Model: Representation and Visualization

3D models are primarily used for:

- Visual representation

- Documentation

- Planning and design

- Communication

- Static analysis

Digital Twin: Operations and Optimization

Digital Twins are used for:

- Real-time monitoring

- Performance optimization

- Predictive maintenance

- Decision support

- Automated control

4. Update Frequency

3D Model: Manual Updates

3D models require manual updates when changes occur. Updates are typically infrequent and require new data collection or modeling work.

Digital Twin: Continuous Updates

Digital Twins update automatically and continuously, often in real-time or near-real-time, as data flows from connected systems and sensors.

5. Intelligence and Behavior

3D Model: Geometric Intelligence

3D models contain geometric intelligence—understanding shape, structure, and spatial relationships. They don’t understand behavior or performance.

Digital Twin: Behavioral Intelligence

Digital Twins understand how systems behave, how they perform under different conditions, and how they might behave in the future. They include behavioral models and predictive capabilities.

6. Interactivity

3D Model: Passive Interaction

Users interact with 3D models by viewing, rotating, measuring, and analyzing. The model doesn’t respond to external changes or provide feedback.

Digital Twin: Active Interaction

Digital Twins respond to changes, provide feedback, trigger alerts, and can even control physical systems. They’re interactive partners in operations.

7. Cost and Complexity

3D Model: Lower Complexity

3D models are relatively straightforward to create and maintain. They require data collection, processing, and modeling expertise but don’t require ongoing data integration.

Digital Twin: Higher Complexity

Digital Twins require:

- Initial modeling (like 3D models)

- Sensor integration and IoT infrastructure

- Data integration systems

- Behavioral modeling

- Ongoing maintenance and updates

When to Use Each Technology

Choose 3D Models When:

- Documentation Needed: Creating records of current conditions

- Visualization Required: Presenting designs or existing states

- Planning Purposes: Supporting design and development

- One-Time Analysis: Single-point-in-time assessment

- Budget Constraints: Limited resources for implementation

- Static Applications: No need for ongoing updates

Choose Digital Twins When:

- Operational Monitoring: Need for real-time system tracking

- Predictive Capabilities: Forecasting future performance

- Optimization Goals: Improving efficiency and performance

- Maintenance Planning: Predictive maintenance requirements

- Remote Management: Controlling systems from distance

- Continuous Improvement: Ongoing optimization needs

Common Misconceptions

Misconception 1: “A 3D Model with Sensors Is a Digital Twin”

While adding sensors to a 3D model is a step toward a Digital Twin, it’s not sufficient. A Digital Twin requires:

- Continuous data integration

- Behavioral modeling

- Predictive capabilities

- Automated updates

Misconception 2: “Digital Twins Are Just Advanced 3D Models”

Digital Twins are fundamentally different. While they may include 3D visualization, their core value lies in:

- Real-time data integration

- Behavioral understanding

- Predictive analytics

- Operational intelligence

Misconception 3: “You Always Need a Digital Twin”

Many applications are perfectly served by 3D models. Digital Twins add value when:

- Real-time monitoring is required

- Predictive capabilities are needed

- Operational optimization is the goal

- Continuous updates are necessary

Integration Possibilities

Starting with 3D Models

Many Digital Twin implementations begin with 3D models:

- Create 3D Model: Establish baseline geometric representation

- Add Sensors: Integrate IoT devices and data sources

- Develop Models: Create behavioral and predictive models

- Enable Updates: Establish continuous data integration

- Evolve to Digital Twin: Transform into full Digital Twin

This evolutionary approach allows organizations to start simple and add capabilities over time.

Real-World Applications in Dubai and UAE

3D Models for:

- Building Documentation: Recording existing building conditions

- Design Visualization: Presenting architectural and engineering designs

- Site Planning: Supporting development planning

- Heritage Preservation: Documenting historical structures

Digital Twins for:

- Smart Buildings: Optimizing building operations and energy use

- Infrastructure Management: Monitoring and maintaining critical infrastructure

- Manufacturing: Optimizing production processes

- Urban Planning: Managing city systems and services

Conclusion

Understanding the difference between Digital Twins and 3D Models is crucial for professionals making technology decisions. While both involve digital representation, they serve fundamentally different purposes:

- 3D Models are excellent for documentation, visualization, and planning

- Digital Twins excel at operational monitoring, optimization, and predictive capabilities

The choice depends on specific needs, goals, and resources. Many organizations benefit from starting with 3D models and evolving toward Digital Twins as needs and capabilities grow.

For professionals in Dubai and the UAE, both technologies offer significant value. The key is understanding which approach best serves your specific requirements and making informed decisions based on clear understanding of capabilities and limitations.

Need Expert Guidance?

At ZID – Zenith InnoDev, we bring 11+ years of mechatronics engineering expertise and 4 years of specialized drone services to help you understand and implement the right digital representation solutions for your needs.

Whether you need 3D models for documentation and planning or are exploring Digital Twin capabilities for operational optimization, we provide expert guidance and professional implementation services.

Contact us today to discuss your digital representation needs and discover which approach best serves your goals.

Internal Links: